Repairing the Port Quarter 2013

December 2012-January 2013

Okay, the front half of the boat has been rebuilt, the gaping holes from the starboard and stern cabin have been repaired, now it's time to address the Port side of the boat.

First, we remove the rotting sections of deck, repair the frames with rot in them, and rebuild it all so it doesn't rot again. Ever.

First, we remove the rotting sections of deck, repair the frames with rot in them, and rebuild it all so it doesn't rot again. Ever.

Clear the deck!

Perhaps there is solace, when working in cold weather, that working hard helps keep you warm.

Or... maybe not.

Gabs is seen here, laboring in the twilight, trying to get rotten planking to break free on the port side deck.

It's an interesting phenomenon that when trying to remove wood from a boat, it either comes out by the handful, or it doesn't want to come off at all.

Or... maybe not.

Gabs is seen here, laboring in the twilight, trying to get rotten planking to break free on the port side deck.

It's an interesting phenomenon that when trying to remove wood from a boat, it either comes out by the handful, or it doesn't want to come off at all.

March 28, 2013

After three months of extensive (and expensive) labor, the galley of Moontide once again appears intact. Now if only the fiberglass deck would put itself on!

Spring, 2013

Here is a summary of cabin repair done by the end of May, 2013:

Starboard Side:

Port side:

Autumn, |

Winter, |

Late Winter, |

May... |

Summer, 2013

June is busting out all over!

We thought it was almost over. Just a little piece that needed replacing on the quarter deck.

Michael & Gabrielle began cutting out rot...

Michael & Gabrielle began cutting out rot...

On the bright side,

This is the "back of the boat." We've removed all of Moontide's bad wood, from bow to transom. If we find any more rot now, it's going to have to be on someone else's boat!

Huzzah!

Huzzah!

To do this, we...

But Before we put the deck on...

We need to make sure everything below deck is in place and working. For instance, replacing worn exhaust hose, broken engine cable fittings, frayed electrical wires, running the propane lines to the new tank location, and building and installing the sub-deck for the Port side lazarette (left) to name a few.

October 2013 Arrives

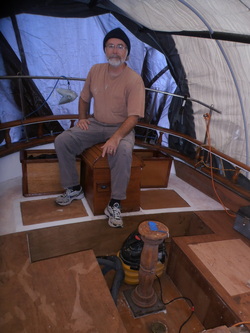

With our new Conestoga wagon Application on, (see Blog) we have space to work on the cockpit area and stay free from the elements.

Here we see Michael dry-testing the the 'saddle' wheel box with its new 'saddle bag' seats on.

That, and the new 'T' shaped wheel well that's in place should make steering the boat easier, if not more user-friendly.

As you can see, a great deal of fiberglassing and finish work has yet to be done.

Here we see Michael dry-testing the the 'saddle' wheel box with its new 'saddle bag' seats on.

That, and the new 'T' shaped wheel well that's in place should make steering the boat easier, if not more user-friendly.

As you can see, a great deal of fiberglassing and finish work has yet to be done.

A nice feature of the new 'Conestoga' tarp is that the back panel is retractable in nice weather, which helps when applying nasty, toxic-smelling things like fiberglass fillers and resins. Here we see Gabrielle and Carmen sitting in the new cockpit, both enjoying a morning cup of coffee, and the warmth that sunshine on the tarp provides the whole boat. Heat is also helpful when you want the resin to harden!